MANUFACTURERS OF HI-TECH LIGHT ALLOY WHEELS

100% MADE IN ITALY TUV-KBA-NAD APPROVED.

Born in January 2006 in the province of Bergamo, SPATH produces one of the largest existing ranges of high-tech light alloy wheels, both in terms of number of the models proposed and possible applications, such as Vans, Buses, Off-road vehicles, and in terms of color customizations, always strictly 100% Made in Italy.

It is also the first Italian company in terms of the number of TUV / KBA approved products for the very demanding German market and beyond. SPATH exports throughout Europe, and overseas, and today offers an original range of products of a quality able to pass strict tests, ensuring each wheel flexibility combined with high productivity that distinguish the company, also thanks to its long experience gained in the sector. Furthermore, we are proud to offer the Italian market one of the widest ranges of NAD approved products.

The production cycle is basically divided into two phases.

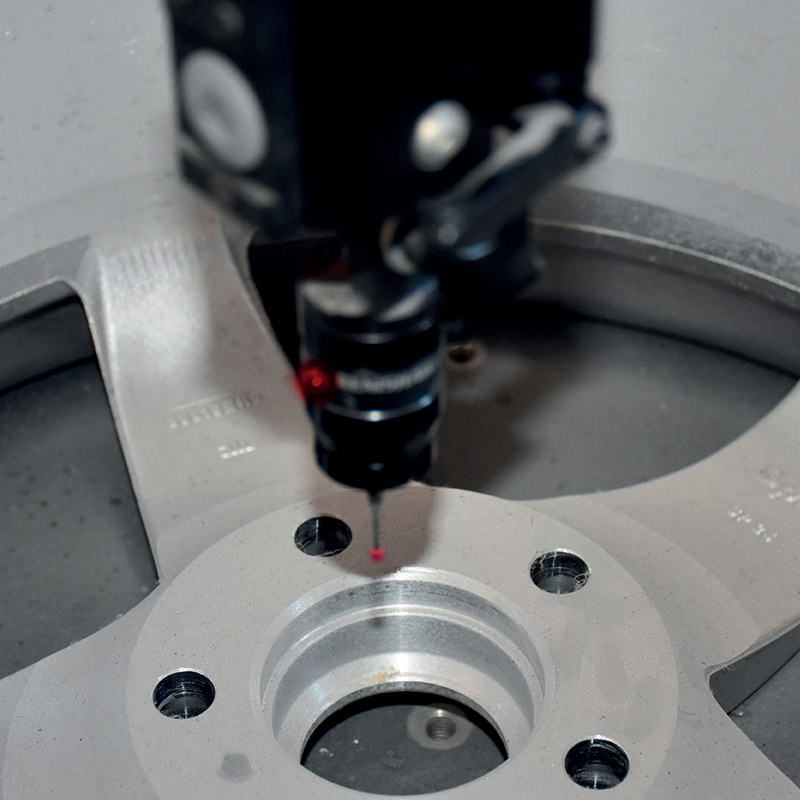

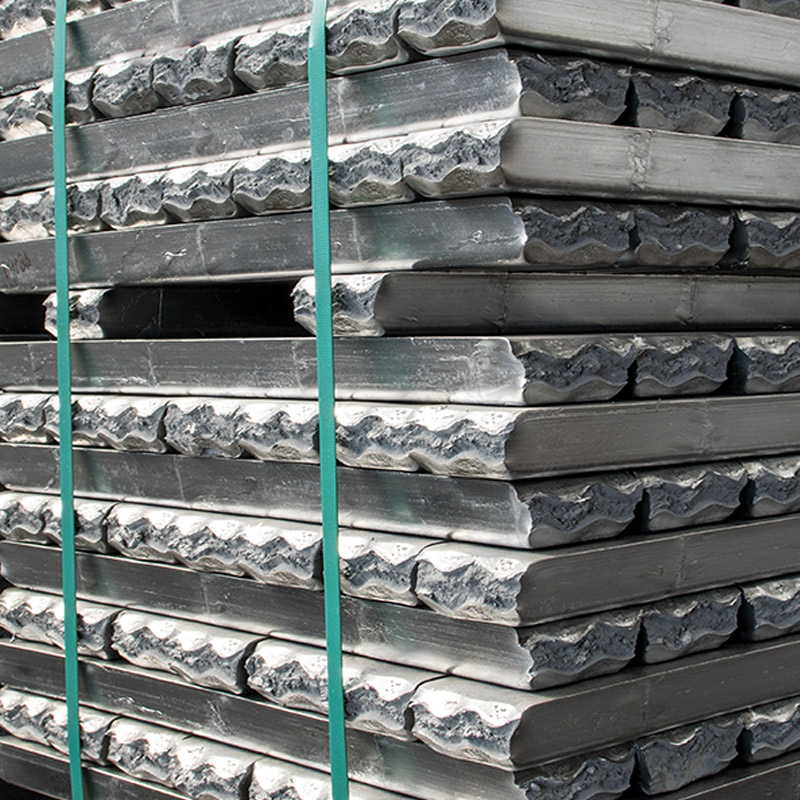

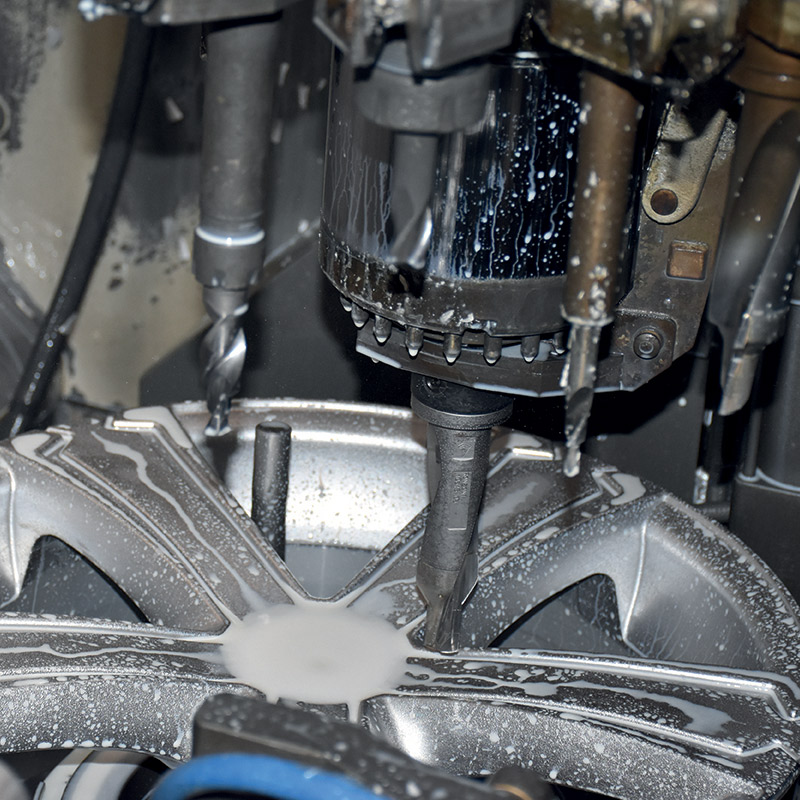

The first is the gravity casting of the metal flow carried out on gravity die casting machines, equipped with a robotic feeding arm. This type of casting allows to obtain structurally suitable castings that guarantee precise mechanical and endurance characteristics. The second phase of the production cycle is mechanical processing, performed using advanced technologies: automatic CNC lathe machines with constant precision.

The process also ensures high productivity and flexibility in the variety of models and sizes.

Before finishing, the wheels undergo radioscopy [100%] and Tubeless control [100%]. During the production cycle, other tests are also performed, such as alloy analysis and dimensional checks. Extreme attention is paid to the finish of the product: the wheels undergo a phosphochromatizing treatment to prevent oxidation. The painting plant has a control laboratory which, at each production cycle, has the task of checking the proper execution of all finishing operations.

Thanks to its quality level, Spath can maintain its commitment to development and expansion on major markets.

PRODUCTION PHASES

Our light alloy wheels are conceived, designed and manufactured entirely in our plant in Gorlago, Bergamo. We proudly state that our product is 100% MADE IN ITALY. We offer the highest quality and the renowned Italian style in a huge range of models for cars, Vans, Suv’s, Off Roads and trailers. Our clients may customize colours and finishes of any wheel. The use of primary alloys, strict tests and a constant research of technological innovation are our mission. The production cycle is divided basically into two phases: casting and mechanical processing.

Both steps are performed by CNC workstations. During the whole production cycle the wheels daily undergo different kinds of tests: X-ray test, Leakage-Tubeless control, Analysis of the alloy, 3D dimensional controls, Balancing and Run-out test. Extreme attention is paid to the finishing of the product. The wheels also undergo a phosphochromatizing treatment to prevent oxidation. Finally, during the packaging our staff checks every wheel with a final visual inspection.